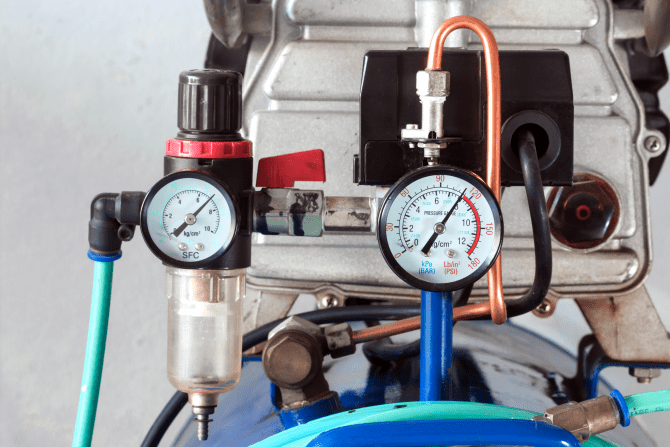

Compressor Service in Pakistan

REACTIVE REPAIR REQUESTS VS PROACTIVE MAINTENANCE

Notification

Reactive Repair Requests

The outdated service model only acts when there is a specific problem, i.e. when a call comes into the Service department because something has gone wrong with product A or B. A couple of standard questions are clarified and then used in an attempt to assess the fault. However, an on-site visit is often required to shed light on the actual issue. The problem of course is when the Service employee does not have the right tool to hand to repair the plant.

Proactive Maintenance

Temperature, infrared, vibration and sound alarms in the machine monitor all the functions and feed this data to the network. Service employees can monitor the developments, while early-warning signals make them aware of upcoming maintenance work. In addition to sensors, the alarm system must also be reliably implemented in the system so that error messages reach the relevant Service department without delay.

Feedback

Reactive Repair Requests

There are no troubleshooting instructions whatsoever for reactive repair requests. Automatic feedback helps to identify the cause of the fault and resolve it more quickly, which in turn saves costs. If the machine operator only knows that they need to carry out maintenance or a repair but not where or to what extent, this information is of little use.

Proactive Maintenance

Intelligent machine systems are able to forward assistance and evaluations from incidents and problems via the IIoT. Advisory maintenance assistants which not only point out specific maintenance activities in a timely manner but engage directly with the Service technician and recommend actions are conceivable here. The machine thus acts as a patient who can determine where the pain is and what intervention is needed to alleviate it.

Service

Reactive Repair Requests

Reactive service only intervenes once it is too late. So the only option that remains is to replace components or dispose of the machine. Both cases mean downtime for the customer. If this lasts too long, the Service team are automatically regarded as a problem and the customer may opt for a different compressed air supplier.

Proactive Maintenance

Thanks to “Connected Services”, the health of a product can be monitored on the manufacturer’s side so that they can inform the customer in good time and avoid more expensive repair measures. Enhanced dialogue with the customer allows manufacturers to focus more intensely on the benefits and the requirements of their products. However, this extended customer dialogue must not become a time guzzler! Many aspects can be processed with automatic customer service.

Optimization

Reactive Repair Requests

At the end of the IIoT value-added chain is the continuous optimization process. Optimization before IIoT was less targeted and expensive. Elaborate test series and long planning phases also have a negative effect on the maintenance service. The principle is: if you don’t know the customer’s concerns, you can’t meet them.

Proactive Maintenance

Once the products are linked to IIoT, their functions can be closely monitored. With 24/7 IIoT, an enormous amount of data can be collected, which helps developers and users to continuously improve the performance of their system. Modern IIoT software enables the creation of a software-based prototype, the so-called “digital twin”, which can be tested under various parameters – without the need for time-consuming test runs in reality. A more precise test phase also allows maintenance units to be effectively shortened.

Learn more about Compressor Service Experts in Pakistan with 41 Years of Compressed Air Excellence