BUYING EFFICIENCY LEADS TO PROFITS

RASTGAR's 11.11 Sales Campaign for Compressor Parts, Whole Year Service Plan, Free Delivery, Free Service, and Warranty Subscription

As the industrial landscape evolves, so does the need for efficient, cost-effective solutions to keep your compressed air systems running smoothly. Rastgar, a renowned name in the compressor industry in Pakistan, has raised the bar with its exclusive 11.11 Sales Campaign. This campaign not only offers incredible savings on compressor parts but also introduces a comprehensive whole Year Service Plan with free delivery and service. To add icing on the cake, Rastgar is inviting businesses to subscribe to their Warranty Program, creating a holistic approach to compressor maintenance. Let’s explore the myriad benefits of seizing this opportunity.

Unbeatable Savings on Compressor Parts:

The 11.11 Sales Campaign is synonymous with irresistible discounts, and Rastgar’s offering is no exception. Businesses can stock up on genuine compressor parts at prices that won’t break the bank. This upfront cost saving sets the stage for a year of efficient and worry-free compressor operation.

Comprehensive Whole Year Service Plan:

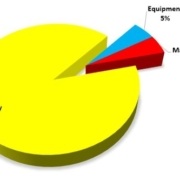

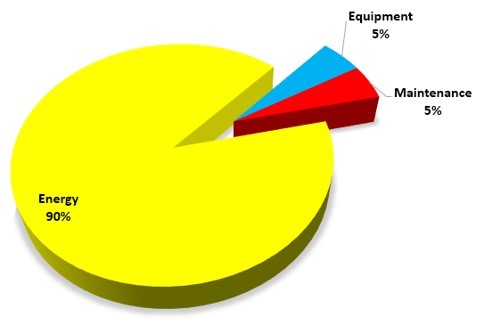

Investing in Rastgar’s Whole Year Service Plan during the 11.11 Sales Campaign is a strategic move for businesses looking to optimize their maintenance budgets. The plan encompasses not only genuine compressor parts but also free delivery and on-site service throughout the year. This comprehensive approach minimizes downtime, maximizes efficiency, and contributes to long-term cost savings.

Free Delivery:

Part of the allure of Rastgar’s 11.11 Sales Campaign is the inclusion of free delivery for compressor parts. Businesses can now save on logistics and transportation costs, ensuring that essential parts reach their doorstep without any additional financial burden. This streamlined delivery process contributes to a hassle-free maintenance experience.

Expert On-Site Service at No Extra Cost:

In addition to free delivery, the Whole Year Service Plan includes on-site service at no extra cost. Rastgar’s team of expert technicians will visit your facility to inspect, maintain, and troubleshoot any issues with your compressors. This proactive approach minimizes the risk of unexpected breakdowns, further enhancing the overall reliability of your machinery.

Warranty Subscription for Added Peace of Mind:

Rastgar goes the extra mile by offering a warranty subscription option during the 11.11 Sales Campaign. Subscribing to the warranty provides an extra layer of protection, ensuring that any unforeseen issues are promptly addressed. This subscription not only enhances peace of mind but also aligns with Rastgar’s commitment to customer satisfaction and long-term partnerships.

Tailored Solutions for Varied Business Needs:

Rastgar understands that one size doesn’t fit all. The Whole Year Service Plan and warranty subscription are designed to be flexible, catering to the unique needs of diverse industries and compressor models. This tailored approach ensures that businesses receive a customized solution that aligns perfectly with their operational requirements.

Golden Opportunity for Businesses: Plan Profits with Rastgar Plan

Rastgar’s 11.11 Sales Campaign is a golden opportunity for businesses to revolutionize their approach to compressor maintenance. By capitalizing on the unbeatable discounts on compressor parts, embracing the comprehensive Whole Year Service Plan with free delivery and service, and subscribing to the warranty, businesses can unlock a year of unparalleled efficiency and savings. Seize the moment on 11.11 and embark on a journey towards a future where compressor maintenance is not just a necessity but a strategic advantage.